Choosing the Right Tevo Tarantula Filament Size

The Tevo Tarantula is a popular 3D printer known for its affordability and versatility. One of the most crucial aspects of achieving successful 3D prints with your Tevo Tarantula is selecting the correct filament size. Choosing the wrong size can lead to a host of issues, from poor print quality and failed prints to potential damage to your printer. This guide will walk you through everything you need to know about Tevo Tarantula filament sizes, ensuring you get the best possible results from your 3D printing endeavors. The correct filament size directly impacts the printer’s ability to feed the material smoothly, extrude it at the proper rate, and ultimately, create accurate and detailed models. Understanding the nuances of filament size is essential for both beginners and experienced users alike.

Understanding Filament Size Basics

Filament size refers to the diameter of the plastic thread that your 3D printer uses to build objects. There are two primary filament sizes you will encounter, and they are not interchangeable. The Tevo Tarantula, like many desktop 3D printers, is designed to work with either 1.75mm or 3.00mm (also referred to as 2.85mm) diameter filament. The size of the filament is a critical factor in how the filament feeds through the printer, how it’s melted, and how precisely it can be extruded through the nozzle. It’s essential to understand the implications of each size before making your selection, as using the wrong size can cause significant printing problems.

Filament Diameter and Its Importance

The diameter of the filament directly affects how the filament feeds through the extruder and nozzle. If the diameter is too large, the filament will not pass through the extruder or nozzle. If the diameter is too small, the extruder might not be able to grip the filament properly, leading to under-extrusion or inconsistent layer adhesion. This can result in weakened prints, a rough surface finish, or complete print failures. The precision of the filament diameter also contributes to the print’s accuracy; variations in diameter can lead to inconsistencies in the extruded plastic volume, causing dimensional inaccuracies in your final print. The picture shows how important the diameter is to the process.

Nozzle Size and Filament Compatibility

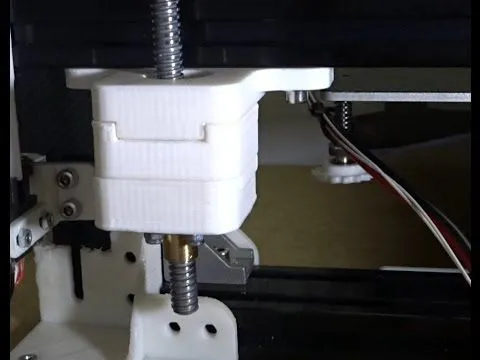

Nozzle size plays a critical role in determining which filament sizes are compatible with your printer. The nozzle is the tiny opening at the end of the hot end where the molten plastic is extruded. If the filament diameter is larger than the nozzle opening, the filament will not be able to pass through, causing a blockage and print failure. The Tevo Tarantula often comes with a standard nozzle size (0.4mm is very common), but this can be changed to suit different printing needs. When selecting a nozzle, ensure that it is compatible with the chosen filament size. Matching the filament size to the nozzle size is vital for smooth and efficient printing. Larger nozzles can generally accommodate larger filament diameters. The picture shows the printer nozzle.

Recommended Filament Sizes for Tevo Tarantula

The Tevo Tarantula is primarily designed to use 1.75mm filament. This is the most common size used in the 3D printing industry. However, some Tevo Tarantula models might be modified or come with components that support 3.00mm filament. It is crucial to confirm the specifications of your specific Tevo Tarantula model before purchasing filament, especially if you did not purchase it new. Check the printer’s documentation or the specifications listed on the manufacturer’s website to determine the correct filament size. Incorrect selection will certainly lead to printing failures.

1.75mm Filament

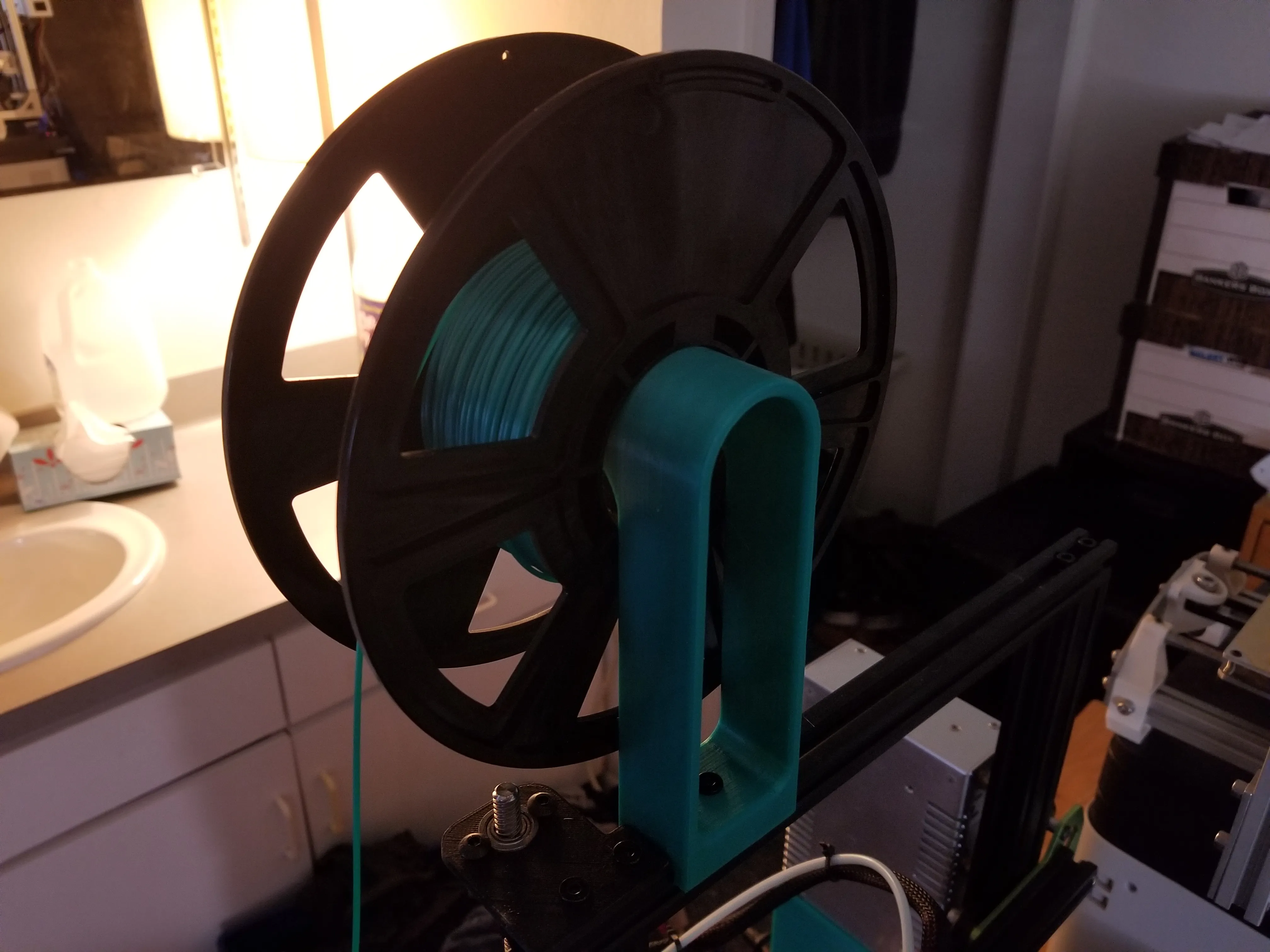

1.75mm filament is the most widely used size for desktop 3D printers, including most versions of the Tevo Tarantula. It’s known for its flexibility and ease of use. This size is suitable for a wide range of materials, including PLA, ABS, PETG, and TPU. 1.75mm filament is also more readily available and often comes in a broader range of colors and materials. It is generally considered the default choice for the Tevo Tarantula unless the printer has been specifically modified for 3.00mm filament. This filament is also considered very easy to handle, and any beginner can use this filament on the printer. The image shows a filament roll with a size of 1.75mm.

2.85mm/3mm Filament

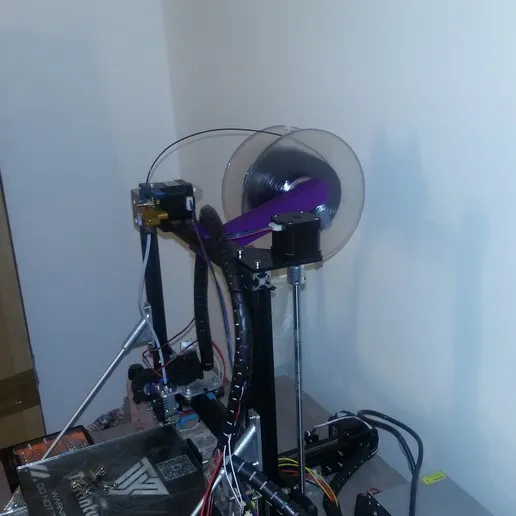

While less common than 1.75mm, some Tevo Tarantula printers can be configured to use 2.85mm (sometimes referred to as 3.00mm) filament. This size is usually found in older 3D printers or those designed for industrial applications. Using 2.85mm filament requires the correct extruder and nozzle. Make sure your printer is compatible with this filament size before purchasing it. If your Tevo Tarantula is not designed for 2.85mm filament, using it can damage your printer. It’s essential to verify compatibility before attempting to print. The image shows a filament roll with a size of 2.85mm.

Factors Influencing Filament Size Choice

Several factors can influence your choice of filament size. The type of material you want to print with, the desired print quality, and the specific specifications of your Tevo Tarantula all play a role in determining the best option for your needs. Considering these aspects will help you make an informed decision and avoid potential issues. The most important thing is the printer specifications and the nozzle size.

Print Quality Considerations

The choice of filament size can significantly impact the quality of your prints. Generally, 1.75mm filament is preferred for detailed prints due to the fine control it offers, as it allows for more precise extrusion. Smaller nozzles are often used with 1.75mm filament, resulting in finer layer lines and a smoother surface finish. However, 3.00mm filament, used with a larger nozzle, can sometimes provide faster print speeds. Print quality also depends on the material used, but filament size plays a role in how precisely the material is extruded.

Material Compatibility

Different filament materials have different properties and requirements. Some materials, like PLA and ABS, are widely available in both 1.75mm and 2.85mm sizes. Others might be less common in one size or the other. Check the availability of the material you want to use in your preferred filament size before making a purchase. Also, consider the specific printing requirements of each material. For example, some materials might require higher printing temperatures or a heated bed, regardless of the filament size. Always refer to the manufacturer’s recommendations for your chosen material to achieve the best results.

Tevo Tarantula Printer Specifications

Always refer to your printer’s specifications to determine the correct filament size. This information should be available in the printer’s documentation, on the manufacturer’s website, or even on the printer itself. The specifications will specify the filament size your printer is designed to use. Using the wrong filament size can lead to many problems, as previously explained. Verify that your printer’s hot end and extruder are also compatible with the chosen filament size.

Nozzle Size and Filament Relationship

The nozzle size is a critical factor in determining which filament size is compatible with your Tevo Tarantula. Make sure that the nozzle’s diameter is compatible with the filament size you choose. The general rule of thumb is that the nozzle diameter should be at least twice the filament diameter to ensure smooth and consistent extrusion. Using the wrong nozzle size can result in clogs, poor print quality, or under-extrusion. Always select the nozzle size that is appropriate for the filament size you are using. The picture shows the printer extruder.

Bed Adhesion and its effect on filament size

Bed adhesion, while not directly related to the filament size, is an important factor in the overall print quality and is indirectly affected by the choice of filament size. Make sure your printer bed is correctly leveled. Bed adhesion is crucial for preventing warping and ensuring that the first layer of your print sticks to the print bed. Consider using bed adhesion aids, such as glue stick or painter’s tape, particularly when printing with materials like ABS that are prone to warping. Proper bed adhesion ensures a successful first layer, which sets the foundation for the entire print. Also, consider leveling, as this will certainly influence bed adhesion.

Troubleshooting Filament Size Issues

Even when you have chosen the correct filament size and taken all the necessary precautions, you might still encounter issues during printing. Several common problems can be related to filament size, including extrusion problems, under-extrusion, and over-extrusion. If you experience any of these issues, troubleshooting steps can help you identify and resolve them. The use of the correct filament size will often prevent many of these issues. Here are some common problems and how to address them.

Extrusion Problems

Extrusion problems can manifest in several ways, such as inconsistent extrusion, filament jams, or complete failure to extrude. Inconsistent extrusion can result in weak layers, gaps in the print, or an uneven surface finish. Filament jams can be caused by a variety of factors, including incorrect filament size, extruder temperature, or a clogged nozzle. Make sure that the filament size is compatible with the nozzle and extruder, and ensure the nozzle is not clogged. The image shows the extrusion problems in the printer.

Under-extrusion

Under-extrusion occurs when the printer does not extrude enough filament, resulting in gaps, weak layers, and poor print quality. Under-extrusion can be caused by several factors, including incorrect filament size, a clogged nozzle, or a problem with the extruder. If you suspect under-extrusion, check the filament size and make sure it matches your printer’s specifications. Increase the extruder temperature slightly to ensure that the filament melts properly, and ensure the nozzle is clean. The image shows under-extrusion problems.

Over-extrusion

Over-extrusion occurs when the printer extrudes too much filament, leading to blobs, bulges, and a generally rough surface finish. This can be caused by incorrect filament size, incorrect extrusion settings, or other printer issues. If you suspect over-extrusion, check the filament size and confirm it matches your printer’s specifications. Reduce the extrusion multiplier in your slicer settings to reduce the amount of filament extruded. The image shows over-extrusion problems.